Laser welding process parameters - shielding gas 2

Jul 03, 20241. Shielding gas blowing method

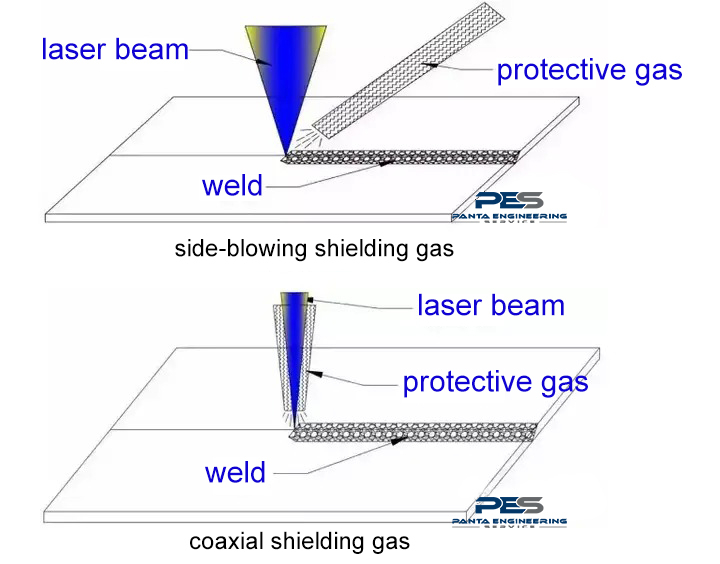

There are currently two main ways to blow shielding gas:

One is side-blowing shielding gas, and the other is coaxial shielding gas. The specific choice of the two blowing methods is a comprehensive consideration of many aspects. In general, it is recommended to use the side-blowing shielding gas method.

2.Principles for selecting shielding gas blowing methods

It is better to use the lateral axis for straight line welds and the coaxial axis for plane closed figures.

First of all, it should be made clear that the so-called "oxidation" of the weld is only a common name. In theory, it means that the weld reacts chemically with harmful components in the air, resulting in poor weld quality. It is common that the weld metal reacts chemically with oxygen, nitrogen, hydrogen, etc. in the air at a certain temperature.

Preventing the weld from being "oxidized" is to reduce or avoid contact between such harmful components and the weld metal in a high-temperature state. This high-temperature state is not just the molten molten metal, but the entire time period from when the weld metal is melted to when the molten metal solidifies and its temperature drops below a certain temperature.

For example, titanium alloy welding can quickly absorb hydrogen when the temperature is above 300℃, oxygen when it is above 450℃, and nitrogen when it is above 600℃. Therefore, the titanium alloy weld needs to be effectively protected after solidification and the temperature drops below 300℃, otherwise it will be "oxidized".

From the above description, it is not difficult to understand that the blown protective gas not only needs to protect the weld molten pool in time, but also needs to protect the welded and just solidified area. Therefore, side-blowing protective gas is generally used, because this protection method has a wider protection range than the coaxial protection method, especially for the area where the weld has just solidified.

For engineering applications, not all products can use side-blowing protective gas. For some specific products, only coaxial protective gas can be used. Targeted selection is required based on product structure and joint form.

3. Selection of specific shielding gas blowing methods

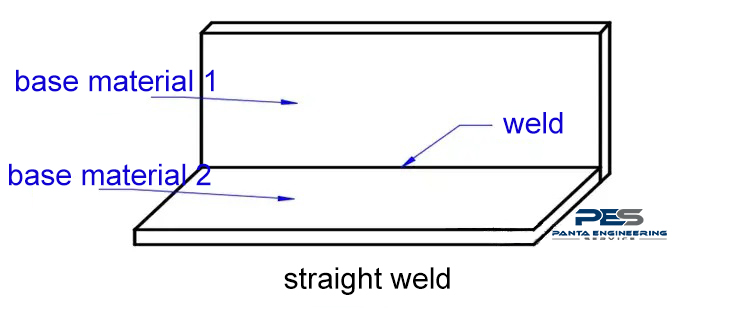

(1) Straight welds

The weld shape of the product is a straight line, and the joint form can be a butt joint, lap joint, internal angle joint or lap weld joint. For this type of product, it is best to use the side-blow shielding gas method.

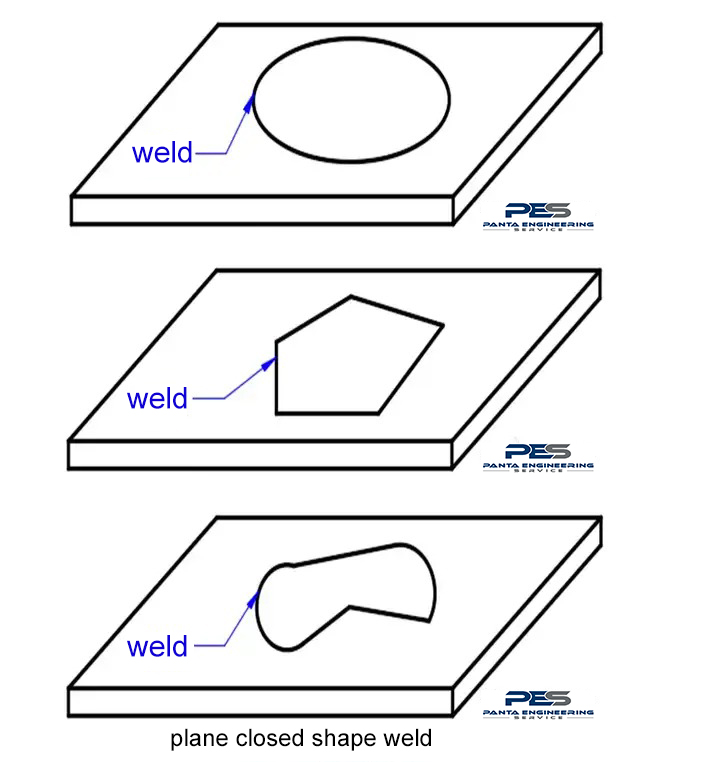

(2) Plane closed figure welds

The weld shape of the product is a closed figure such as a plane circle, a plane polygon, or a plane multi-segment line. The joint form can be a butt joint, lap joint, lap weld joint, etc. For this type of product, it is best to use the coaxial shielding gas method.

The selection of shielding gas directly affects the quality, efficiency and cost of welding production. However, due to the diversity of welding materials, the selection of welding gas is also relatively complicated in the actual welding process. It is necessary to comprehensively consider the welding material, welding method, welding position, and the required welding effect. Only through welding testing can a more suitable welding gas be selected to achieve better welding results.

Come possiamo aiutarti?